Product

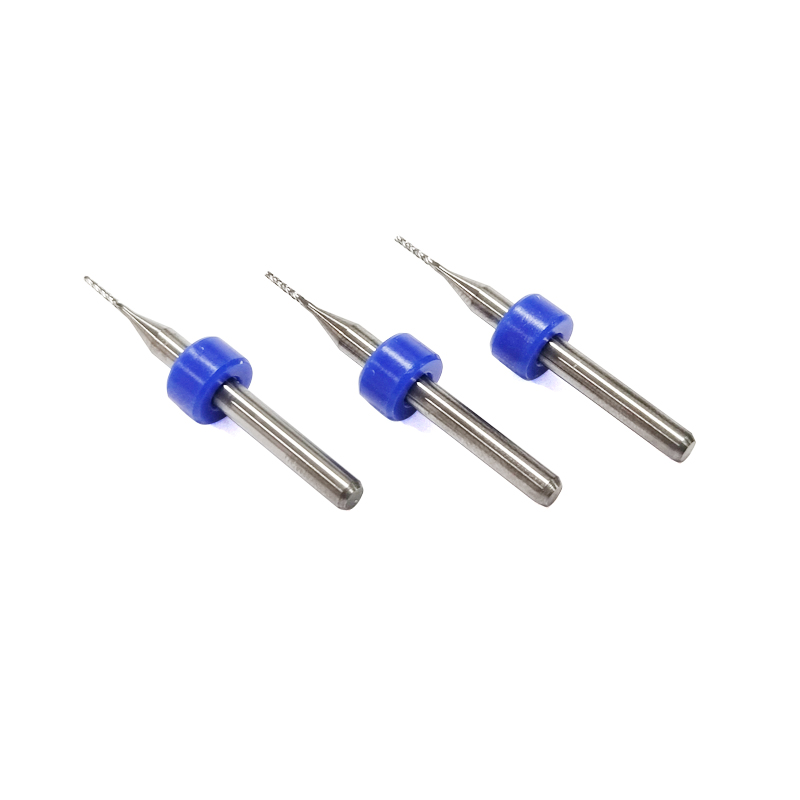

PCB milling cutter

Features

This tungsten carbide PCB milling cutter is exclusively designed for our PCBA depaneling machines/routers. Leveraging the equipment's unique functionality, it enables three-stage graded usage: initial stage for high-precision depaneling, middle stage for regular processing, and later stage for rough machining. This fully utilizes the tool's entire lifecycle value, resulting in more cost savings compared to traditional usage methods. Available in right-hand spiral (for top-side extraction) and left-hand spiral (for bottom-side extraction) designs, with diameters ranging from 0.8-3mm and ±0.05mm tolerance, ensuring smooth, burr-free edges across all processing stages.

Contact Us

-+

ADD to Quote

Product Details

Premium Tungsten Carbide PCB Milling Cutter

Exclusive for PCBA Depaneling Machines/Routers

1. Superior Tungsten Carbide Material: Three-Stage Lifecycle Utilization

2. Spiral Direction Matching: Optimize Dust Extraction for Depaneling

3. Versatile Diameter Range: Perfect for All Depaneling Needs

4. Perfect Compatibility: Designed for PCBA Depaneling Equipment

Why Choose Our Tungsten Carbide PCB Milling Cutter?

Contact us for bulk pricing or custom diameter requests.

Next:The last product

Related Suggestion

Online Consultation

RASEM Automation Technology Co., Ltd

20 years experiences textile machine manufacturer and exporter

86+19065349218

lyj@rasem.com.cn