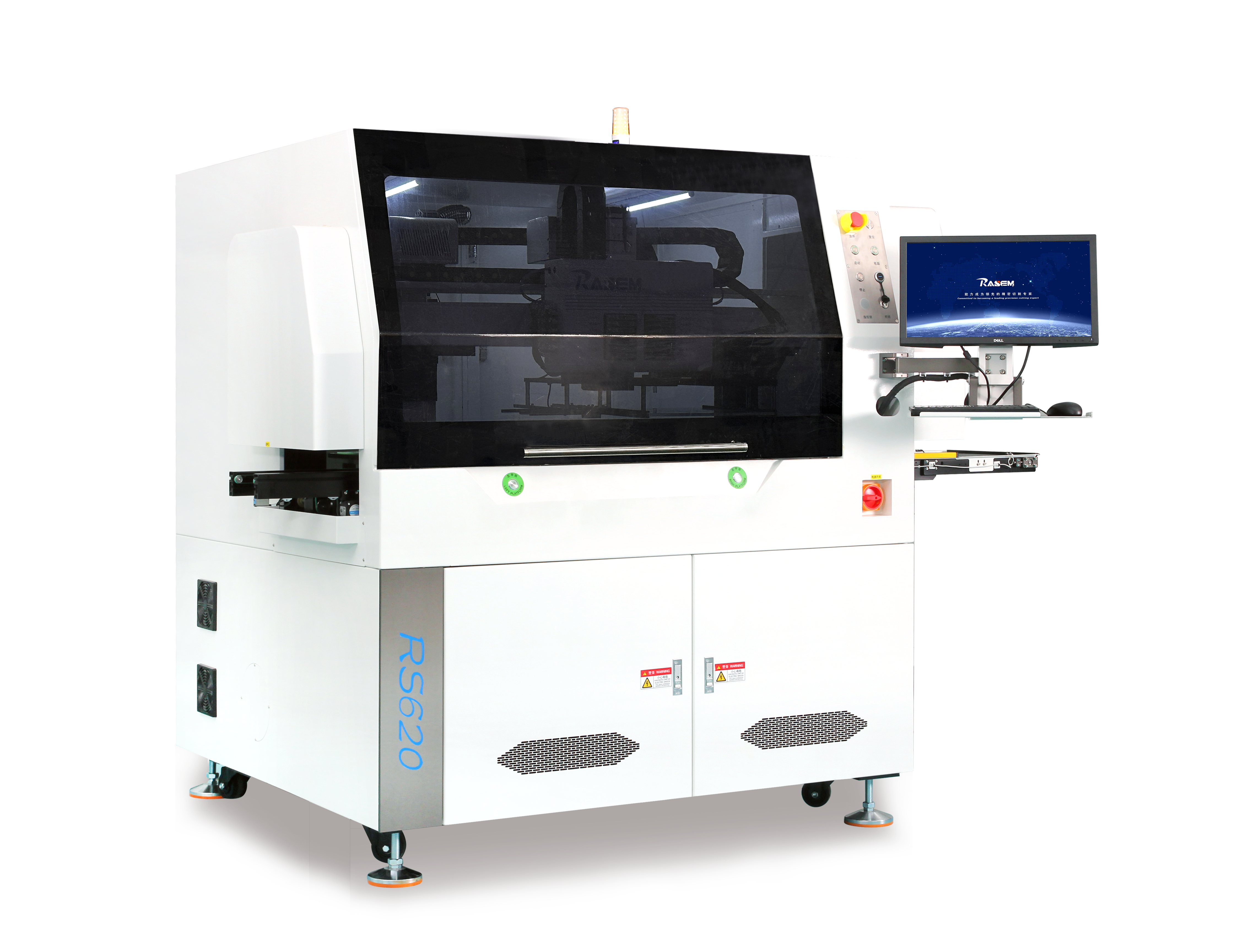

Product

Features

Applications: PCB boards for 3C digital products, small household appliances, automotive electronics, GPS, boards, SMT/EMS, home appliances, solar energy, automotive electronics, military, semiconductor, medical devices, etc.

Product Details

Introduction

- The RS-620 inline fully automatic PCB depaneling machine is designed to meet the needs of automated factories. It features automatic feeding, cutting, and discharging, making it suitable for high-efficiency production environments.

- The machine automatically adjusts the board width to receive PCBs and sorts finished products and waste after cutting, significantly reducing labor costs.

- Equipped with a high-speed CCD vision automatic correction system, the RS-620 greatly enhances cutting accuracy and operational efficiency.

- Utilizing a high-speed spindle for PCB cutting, the machine ensures low cutting stress, high precision, and compatibility with PCBs of any shape.

- The dual-platform design allows simultaneous depaneling and PCB placement, improving overall work efficiency. It is particularly suitable for industries with high-volume production, such as communications, medical devices, automotive electronics, and 3C electronics.

High Precision

CCD Automatic Recognition and Compensation:The machine uses CCD to automatically recognize mark points for positioning and compensation, ensuring high-precision cutting.

Advanced Vision System:This system improves programming efficiency, convenience, and stability.

Dual-Station Platform: Driven by servo motors and ball screws, the dual-station platform ensures higher equipment precision.

High Efficiency

Dual-Station Platform: Allows simultaneous PCB depaneling and board replacement, reducing waiting time for placing PCBAs.

Servo and Ball Screw Drive:Ensures higher speed, lower cutting stress, and better stability and durability.

Dual-Station Dual-Spindle: Increases production by 80% (optional).

User-Friendly Operation

Windows 7 Interface: The machine features a bilingual (Chinese and English) Windows 7 operating interface, making programming simple and easy to learn.

High Quality

Anti-Static Brush Dust Collection: The top dust collection system uses anti-static brushes, achieving a dust collection rate of up to 90% for high cleanliness.

Low Cutting Stress: The cutting stress on PCBAs is less than 200με, resulting in smooth and flat cutting surfaces.

High-Reliability Cutting

Four-Axis Servo Drive: The machine uses a four-axis servo drive system for cutting, powered by an imported high-speed spindle.

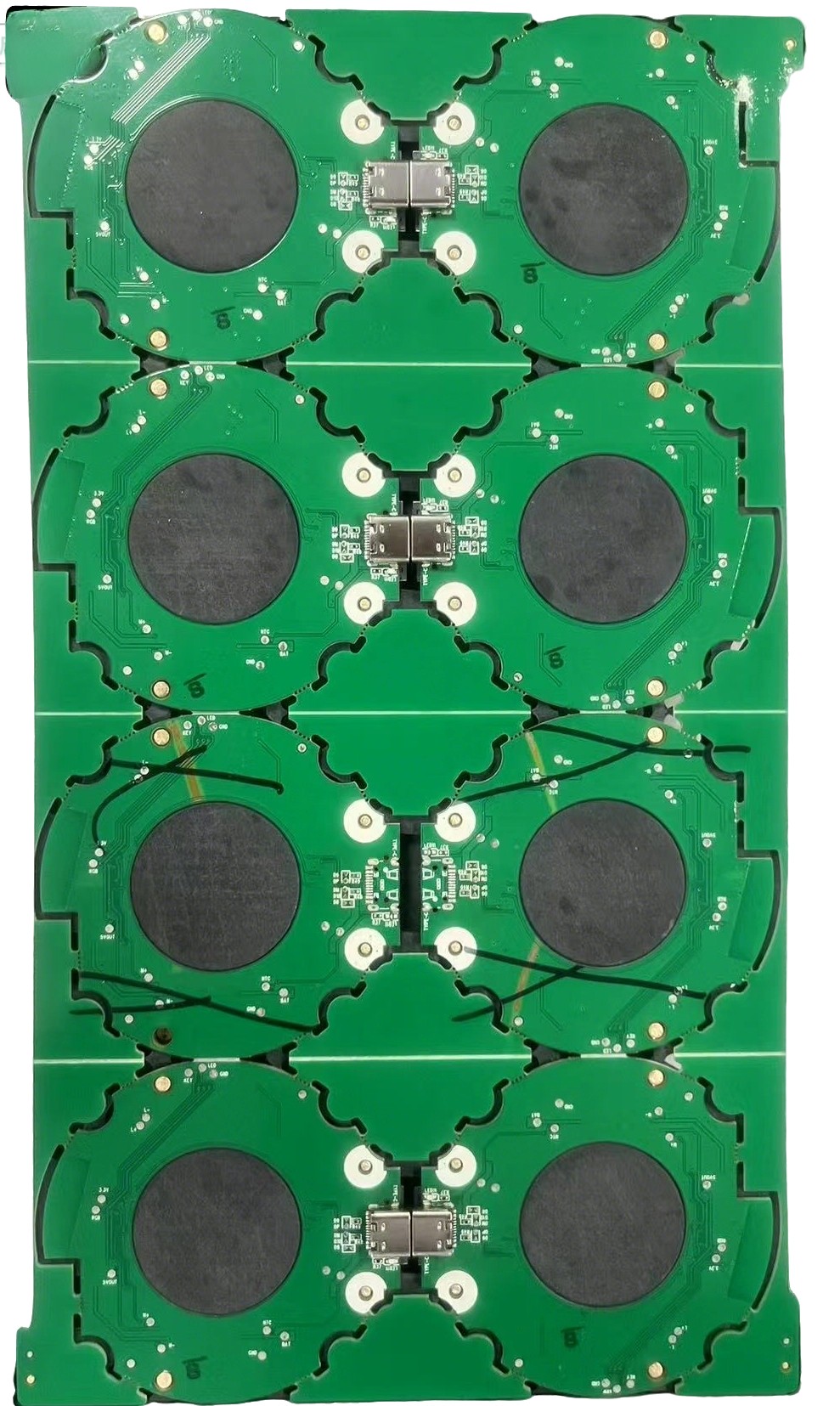

Versatile PCB Shapes: Suitable for various PCB shapes, including straight lines, L-shapes, U-shapes, circles, arcs, and irregular shapes.

Device Parameters

| Main Equipment Size | 1450x1330x1680mm (L*W*H) |

| Effective Cutting Dimension | 350x310mm (L*W) |

| Processing Platform | Double Platform |

| Feeding Method | Orbital Feeder |

| Discharging Method | Rail Discharge / Belt Discharge / Sliding Table Discharge Plate |

| Shifting Method | Vacuum Adsorption Transfer |

| Height of Equipment in Use | 900±20mm |

| Flow Direction | Left to Right / Right to Left |

| Machine Repeatability Accuracy | ±0.01mm |

| Cutting Accuracy | ±0.05mm |

| Maximum Movement Speed | XY: 1000mm/s, Z: 500mm/s |

| Maximum Movement | X Axis: 880mm, Y1/Y2 Axis: 730mm, Z Axis: 100mm |

| Distance Movement by Robot Arm | X Axis: 980mm, Z Axis: 100mm |

| Spindle Rotating Speed | MAX: 80000RPM |

| Milling Cutter Replacement Method | Automatic Replacement |

| Cutting Speed | 1~100mm/s |

| Operation Interface | Visual Operation Window (Windows 10 System) |

| Programming Method | Color CCD Image Didactic Input, Offline Programming |

| Program Backup | USB Interface |

The cutting effect is as shown in the figure.

Related Suggestion

Online Consultation

20 years experiences textile machine manufacturer and exporter